Transforming Upholstery Projects with the Right Tools

Upholstery involves much more than simply covering furniture with fabric. It’s a skilled process requiring precision, creativity, and the right tools. From restoring vintage chairs to crafting custom sofas, upholstery allows you to transform worn-out or plain pieces into beautiful, comfortable, and functional furniture.

Whether you’re aiming to refresh your home décor or work on a client project, upholstery requires a variety of techniques, from cutting and stapling to shaping foam and assembling frames.

Each of these steps benefits from the use of specialized tools designed to make your work not only easier but also more professional and durable.

Crafting Comfort and Style: An Overview of Upholstery Work

Upholstery work is a multifaceted craft that combines artistic vision with technical skills. It typically involves taking an old or unfinished piece of furniture and making it functional and stylish by adding layers of fabric, padding, springs, and foam.

Projects can range from reupholstering a well-loved chair to creating custom-built sofas and sectionals.

For many, upholstery is an opportunity to repurpose or restore, giving new life to items that might otherwise be discarded. Whether you’re handling a family heirloom or a recent flea-market find, upholstery allows you to add a unique, personal touch.

The entire process can be detailed, requiring careful planning and precise measurements for every part, which makes choosing the right tools critical to achieving the best results.

Why Quality Tools are the Secret to Flawless Upholstery Finishes

When working on upholstery projects, the right tools are essential to getting a smooth, professional finish.

Using tools specifically designed for upholstery tasks can drastically reduce the time and effort needed to complete a project.

For example, a pneumatic staple gun can secure fabric more firmly than a manual staple gun, while a foam cutter will allow you to create smooth, precise edges that improve comfort and aesthetics.

High-quality tools also minimize wear and tear on your materials and equipment, saving you money over time.

Without the right tools, it’s easy to end up with uneven seams, misaligned fabric, or loose staples that can quickly detract from the finished look and durability of the furniture.

In essence, investing in good tools not only simplifies the process but also enhances the quality of your work, helping you achieve a lasting, polished result.

Unlock Your Upholstery Potential: What You'll Gain from This Guide

This guide will provide you with an in-depth look at the most important tools you need for successful upholstery projects.

By the end of the article, you’ll understand which tools are necessary for different stages of upholstery work and why they’re beneficial.

Whether you’re new to DIY projects or an experienced professional looking to expand your toolkit, this guide will help you make informed decisions. You’ll learn how each tool can be used to streamline your work, boost your efficiency, and deliver a high-quality finish that will stand the test of time.

Additionally, we’ll share tips on what to look for when purchasing these tools, including recommended features and safety considerations.

With these insights, you’ll be equipped to tackle upholstery projects with confidence, creating furniture pieces that showcase your skill and creativity.

Staple Guns: The Essential Tool for Securing Fabric with Ease

Staple guns are an invaluable tool in upholstery, allowing you to secure fabric quickly and securely onto frames with minimal effort.

A staple gun is one of the foundational tools in upholstery because it enables you to attach fabric in precise, snug lines, ensuring a tight fit and a professional look.

Staple guns come in various models, each suited to different tasks and user preferences. Choosing the right staple gun can make a significant difference in both the quality and speed of your upholstery projects.

With the right staple gun in hand, you’ll be able to handle everything from minor repairs to full reupholstery jobs, giving your furniture a lasting, flawless finish.

Types of Staple Guns: Manual, Electric, and Pneumatic

When it comes to staple guns for upholstery, you’ll encounter three primary types: manual, electric, and pneumatic.

- Manual staple guns are the most affordable option and are best suited for smaller projects, but they require more physical effort.

- Electric staple guns reduce strain by using a power source to drive the staples, making them ideal for larger projects where a consistent, fast stapling speed is needed.

- Pneumatic staple guns, which are powered by an air compressor, are typically used by professionals for heavy-duty projects, as they offer the highest speed and driving power.

Each type has its pros and cons, with manual guns being lightweight and affordable but labor-intensive, while pneumatic guns deliver powerful, efficient results but require an air compressor and tend to be pricier.

Choosing the right one depends on your project size, frequency of use, and comfort level.

Recommended Features: Power, Ease of Use, and Staple Compatibility

When selecting a staple gun for upholstery, consider features that enhance usability, precision, and adaptability.

Adjustable power settings are particularly useful, allowing you to control how deeply the staple is driven, which is important when working with different materials.

Ergonomics is another critical factor; a comfortable handle and lightweight design can prevent hand strain, especially on longer projects.

Staple size compatibility is essential as well since upholstery tasks may require various staple lengths to achieve the desired hold. Some staple guns even offer a nose extension for better reach into tight corners, which can be helpful for more detailed upholstery work.

By focusing on these features, you’ll ensure that the tool you choose meets the demands of your project, enhancing efficiency and comfort.

Different Types of Foam Cutters: Choosing the Right Tool for Your Project

Foam cutters are essential for creating custom upholstery shapes, allowing for smooth, precise cuts that make a difference in both comfort and appearance.

There are three primary types of foam cutters used in upholstery: manual cutters, electric foam cutters, and hot-wire cutters.

- Manual cutters, such as serrated knives or hand saws, are affordable and versatile for basic cuts but can lack precision on thicker foam.

- Electric foam cutters, which use a powered blade, allow for smoother cuts with less effort, making them ideal for detailed work or thicker foam sheets.

- Hot-wire foam cutters use a heated wire to melt through the foam, providing ultra-smooth cuts that are especially useful for creating complex shapes or working with dense foam.

Each cutter type has unique advantages, and selecting the right one depends on the thickness, density, and shape of the foam required for the project.

Key Features for Efficiency: Blade Sharpness, Control, and Comfort

When selecting a foam cutter, several key features can greatly enhance efficiency and ease of use.

Blade sharpness is crucial for achieving smooth edges and reducing material waste, especially when working with thick foam.

For electric and hot-wire cutters, adjustable power and heat control are valuable features that allow you to adapt the tool to different foam densities and thicknesses, ensuring a clean cut without melting or tearing.

Ergonomics are equally important, particularly for electric models; a comfortable, well-balanced handle reduces strain, allowing for more precise control.

Some foam cutters also offer adjustable cutting angles and depth controls, which can be particularly helpful in achieving custom shapes.

Prioritizing these features will help streamline your work and improve the overall quality of your upholstery projects.

Why Foam Cutters Are Essential: Ensuring Comfort and a Custom Fit

Foam cutters are indispensable in upholstery because they allow for the precise shaping necessary to achieve a comfortable, tailored fit in cushions and seats.

Properly cut foam not only contributes to the comfort of a piece but also affects its appearance, as ill-fitting foam can lead to wrinkles or unevenness in the fabric.

By allowing for smooth, accurate cuts, foam cutters ensure that every cushion or padding layer matches the dimensions of the furniture frame, creating a snug fit that improves both aesthetics and functionality.

Foam-cutting tools are also essential for producing custom shapes that standard foam pieces don’t offer, which can make all the difference when working with unique or irregular furniture designs.

Ultimately, using the right foam cutter enhances both the craftsmanship and comfort of upholstery projects, resulting in a professional finish that lasts.

Heavy-Duty Scissors vs. Rotary Cutters: Choosing the Right Tool for Your Needs

In upholstery work, both heavy-duty scissors and rotary cutters are essential tools, each with distinct advantages and best-use scenarios.

Heavy-duty fabric scissors are known for their strength and versatility; they’re ideal for making detailed cuts, especially in areas where precision around corners or curves is required.

Scissors also offer greater control in tight spots, making them a popular choice for intricate fabric shapes.

However, they can become tiring to use over time, particularly on thicker materials.

Rotary cutters, on the other hand, are excellent for long, straight cuts and are perfect for cutting through multiple layers of fabric in one go.

They’re fast and efficient but require a stable cutting mat underneath and may be harder to control in tight, curved areas.

While both tools are valuable, choosing between them depends on the specific demands of each project, with scissors often preferred for precision and rotary cutters for speed.

Top Features to Look For: Blade Sharpness, Comfort, and Durability

When choosing scissors or rotary cutters for upholstery, there are a few key features that can make a significant difference in performance.

Blade sharpness is paramount; a sharp blade ensures clean cuts without fraying the fabric and reduces the need for multiple passes, which can damage the material.

For heavy-duty scissors, grip comfort is essential, especially if you’ll be working on extended projects where hand fatigue can become an issue.

Look for ergonomic handles that reduce strain. Durability is also crucial, as upholstery fabrics like leather or thick upholstery-grade fabrics can wear down standard scissors quickly, so investing in high-quality, durable blades is wise.

With rotary cutters, blade size and safety features are important to consider, as larger blades handle thicker materials better, and safety guards help prevent accidents.

By prioritizing these features, you’ll have tools that not only make your work easier but also last longer.

Common Applications: When to Use Scissors vs. Rotary Cutters

In upholstery projects, knowing when to use scissors versus a rotary cutter can improve both efficiency and precision.

Heavy-duty scissors are ideal for detailed work, such as cutting around curves, corners, or small areas where control is essential. They’re also excellent for working with upholstery accessories like piping or welting, where precision is critical.

In contrast, rotary cutters excel at creating straight lines and are perfect for large pieces of fabric where long, clean cuts are needed.

They’re particularly useful for prepping multiple layers at once, saving time and creating consistent shapes for upholstery padding or fabric panels. Using a rotary cutter on a cutting mat also reduces the chance of material shifting, ensuring a perfect cut every time.

By understanding the strengths of each tool, you can apply them strategically for smoother, cleaner cuts tailored to the demands of each part of the project.

Versatile Tools for Frame Work: Screwdrivers, Drills, and Mallets

When it comes to upholstery projects, frame adjustments and assembly are just as important as fabric and padding.

Screwdrivers, drills, and mallets are versatile tools that make handling these tasks more efficient.

- Screwdrivers, whether manual or electric, are essential for tightening and adjusting screws, providing stability to the frame.

- Drills offer more power and speed for adding new screws or removing old ones, which is particularly useful for heavy-duty frames or when reassembling a piece.

- Finally, mallets come in handy for tapping pieces into place without damaging the wood or metal, helping achieve a snug fit for components like joints, legs, or other structural parts.

Together, these tools allow for precise control over frame work, ensuring each piece is secure and stable before moving on to fabric and cushioning.

Important Features: Power, Control, and Compatibility

When selecting screwdrivers, drills, and mallets for upholstery, several key features enhance their effectiveness.

Power is critical for drills, particularly cordless models with adjustable speed settings, as upholstery often requires variable force to avoid overdriving screws. Ease of control is another important factor, especially for electric screwdrivers and drills; a well-balanced, ergonomic grip ensures comfort during extended use.

Compatibility with upholstery tasks is also essential; for example, a drill with interchangeable bit sizes allows for flexibility in working with different screws and frame materials.

Mallets should have a durable, non-marring head to prevent damage to delicate frame components.

By focusing on these features, you can ensure that each tool is equipped to handle the unique demands of upholstery, from securing screws in tight spaces to safely adjusting frame pieces.

Different Types of Pliers: Needle-Nose, Slip-Joint, and Tack Pliers

Pliers are essential in upholstery work, especially for removing old fabric, tacks, and staples from furniture.

There are several types of pliers that each serve unique functions: needle-nose pliers, slip-joint pliers, and tack pliers.

- Needle-nose pliers are perfect for reaching into tight areas and grabbing small staples or tacks that might otherwise be hard to access.

- Slip-joint pliers offer versatility with their adjustable grip, making them useful for a variety of tasks, from pulling fabric to holding onto larger staples.

- Tack pliers are specifically designed for upholstery, with flat, beveled edges that make it easy to pry out staples and tacks without damaging the fabric or frame.

Each type of plier has its place in upholstery, providing the precision and control needed for efficient, damage-free removal of old materials.

Features That Make a Difference: Comfort, Grip, and Durability

Selecting the right pliers, tack remover or ice pick is about more than just the tool type; certain features make these tools far more effective and comfortable.

Handle comfort is key, especially during extended projects, so look for pliers with ergonomic, cushioned grips that reduce hand strain. Grip strength is another important feature; pliers with strong, non-slip jaws make it easier to pull out stubborn staples and tacks, giving you better control with less effort.

Durability is essential, as upholstery work often involves heavy-duty materials that can wear down standard tools quickly.

Tack removers with a sturdy, forged-steel build and corrosion-resistant finish will stand up to frequent use, and sharp, beveled edges on tack pliers help get under fasteners without damaging the surrounding materials.

Investing in high-quality tools with these features will ensure they perform well and last through multiple projects.

Why They’re Needed in Upholstery: Removing Fabric and Fasteners with Ease

Pliers, tack removers and Ice Picks are invaluable in upholstery, as they simplify the often tedious process of removing old fabric and fasteners without causing damage.

Removing staples and tacks by hand can be challenging and time-consuming, but the right tools make it faster and more efficient.

Needle-nose and tack pliers allow you to grip and remove staples cleanly, while tack removers are specifically shaped to lift out old tacks without bending or breaking them.

These tools help protect the furniture frame, ensuring it stays intact and undamaged for the reupholstering process.

They also reduce the risk of tearing the existing fabric when you need to reuse or repurpose it, making pliers and tack removers essential for anyone looking to achieve a smooth, professional finish in their upholstery projects.

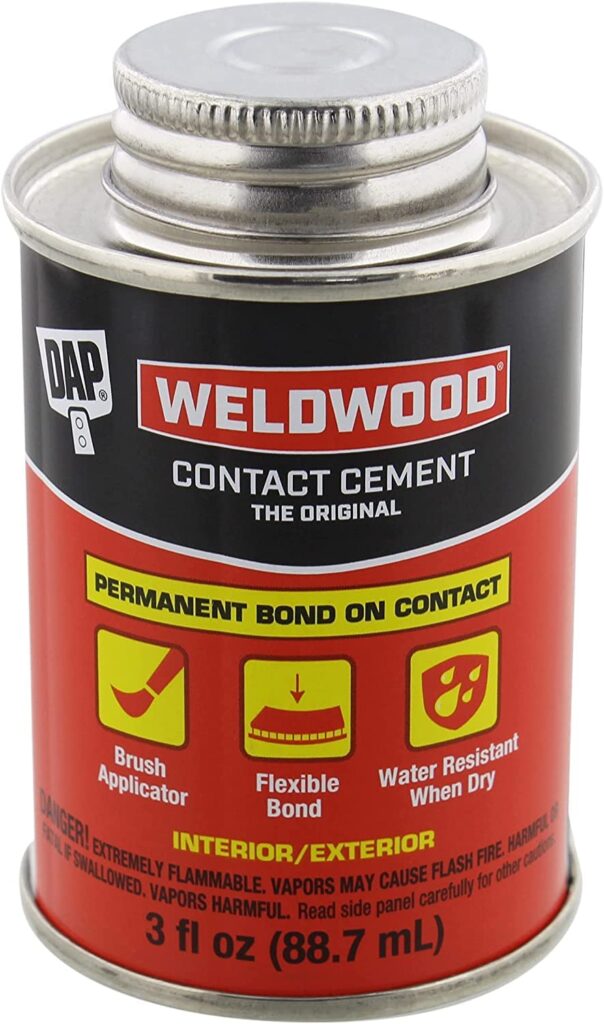

Types of Upholstery Glue: Finding the Right Adhesive for Your Project

When it comes to upholstery, choosing the right adhesive is crucial for achieving a durable and professional finish.

There are several types of upholstery glue available, each designed for specific applications.

Spray glue is a popular choice for its ease of use and ability to cover large areas quickly, making it ideal for bonding fabric to foam or securing multiple layers together.

Other options include liquid adhesives that provide strong bonds for detailed work, hot glue, which offers instant adhesion for quick fixes, and contact cement, which is excellent for permanent bonds but requires careful application.

Each adhesive type has its advantages and is suited to different tasks; for instance, spray glue is perfect for lightweight materials, while contact cement works best for heavier fabrics that need a robust bond.

Understanding these differences helps you select the right adhesive for your upholstery needs.

Top Qualities to Look For: Key Features in Adhesives

When selecting spray glue or any upholstery adhesive, certain qualities are essential to ensure optimal performance.

Drying time is one of the most critical factors; fast-drying adhesives allow for quicker project completion, while those with longer drying times may be beneficial for repositioning materials before setting.

Strength is another vital characteristic; a strong adhesive will provide a lasting bond that can withstand the stresses of daily use, particularly in furniture applications.

Flexibility is equally important, as upholstery projects often require adhesives that can adapt to the movements and wear of the materials without cracking or losing adhesion.

Other features to consider include ease of application, coverage area, and whether the adhesive is water-resistant or heat-resistant.

Prioritizing these qualities ensures you choose an adhesive that meets the specific demands of your upholstery project.

Applications in Upholstery: Where Spray Glue Excels

Spray glue is a versatile tool in upholstery, ideal for various applications that require quick and secure bonding.

One of the most common uses is bonding foam layers together, providing a smooth, consistent base for fabric application.

This is particularly useful when creating custom cushions or padding, as spray glue allows you to adhere multiple layers of foam seamlessly.

Additionally, spray glue is excellent for securing fabric to foam or other materials, ensuring a tight fit without the need for heavy staples or stitching.

It is also useful for attaching lightweight trims or decorative elements, giving you the flexibility to create detailed designs with ease.

However, proper ventilation is important when using spray adhesives, as the fumes can be strong.

Overall, spray glue simplifies the upholstery process, enabling you to achieve a professional finish with minimal effort.

Why an Air Compressor Is Useful: Enhancing Tool Performance

An air compressor is an invaluable asset for upholstery projects, especially when it comes to powering pneumatic tools like staple guns and nailers.

These tools utilize compressed air to deliver consistent and powerful performance, making the task of fastening fabric or upholstery materials significantly more efficient than manual methods.

With an air compressor, you can achieve faster results and reduce the physical effort involved in projects, as pneumatic tools require less manual labor. Additionally, pneumatic staple guns can drive staples more deeply and evenly into various materials, ensuring a strong hold without damaging the fabric.

By providing a reliable power source, an air compressor enhances the overall quality of work, allowing for more professional results in upholstery.

Features to Consider: Finding the Right Compressor for Your Needs

When selecting an air compressor for upholstery tasks, several key features should be taken into account to ensure you choose the right one for your projects.

Size matters, as smaller compressors are generally more portable and suitable for home use, while larger models offer increased power but can be cumbersome to transport.

Power output, typically measured in horsepower or CFM (cubic feet per minute), is essential for ensuring that the compressor can handle the demands of your pneumatic tools.

A higher CFM rating allows for more efficient operation, particularly when using multiple tools or working on larger projects. Portability is another important feature; look for compressors with wheels or lightweight designs if you plan to move it frequently.

Additionally, consider features like noise levels, tank size, and recovery time to find a compressor that best suits your workspace and upholstery needs.

Best Projects for an Air Compressor: Maximizing Efficiency in Upholstery

Air compressors are particularly beneficial for upholstery projects that require extensive fastening or repetitive tasks.

For instance, when reupholstering furniture, a pneumatic staple gun powered by an air compressor can quickly and efficiently attach fabric to frames, ensuring a tight and secure fit.

This is especially helpful when working with thick materials like leather or multiple layers of fabric and padding, where manual stapling can be labor-intensive and time-consuming. Additionally, air compressors excel in projects involving large pieces of furniture, such as sofas or chairs, where a consistent and strong hold is crucial for durability.

Other applications include attaching trim or decorative elements, as well as securing foam layers to frames, where precise fastening is essential.

By integrating an air compressor into your upholstery toolkit, you can enhance both productivity and quality, making it an invaluable investment for serious upholsterers.

Common Safety Gear: Essential Items for Protection

When engaging in upholstery work, it’s crucial to prioritize safety by utilizing appropriate gear. Common safety items include gloves, masks, and eye protection.

Gloves are important for protecting your hands from sharp tools, chemicals, and rough materials.

Depending on the type of work, you may opt for cut-resistant gloves or those designed for grip and dexterity.

Masks are essential when working with spray glue adhesives, paints, or solvents, as they help filter out harmful fumes and prevent respiratory issues.

Eye protection is equally important, especially when using power tools, as flying debris or splashes from chemicals can cause serious injuries. By equipping yourself with these basic safety items, you create a safer workspace and reduce the risk of accidents during your upholstery projects.

Why Safety Is Important in Upholstery: Understanding the Hazards

Upholstery work can involve various hazards that make safety gear essential.

One of the primary risks includes the use of sharp tools, such as scissors, staple guns, and knives or razor blades, which can cause cuts or puncture wounds if not handled carefully.

Additionally, many upholstery materials and adhesives contain chemicals that may release harmful fumes or irritants, necessitating proper ventilation and protective masks to safeguard your respiratory health.

Heavy lifting is also common in upholstery, especially when moving large pieces of furniture, which can lead to strains or injuries if not done correctly.

Recognizing these hazards is vital for creating a safe working environment, allowing you to focus on your projects without the worry of potential injuries.

Summary of Key Tools: Recapping Essentials for Success

Throughout this guide, we’ve explored a range of essential tools that are crucial for successful upholstery projects.

From staple guns that secure fabric layers with ease to foam cutters that provide precision in shaping materials, each tool plays a vital role in achieving professional results.

Scissors and fabric cutters offer clean cuts, while screwdrivers, drills, and mallets facilitate frame adjustments and assembly.

Additionally, pliers, tack removers, or ice picks simplify the process of removing old upholstery, and spray glue provides a versatile adhesive solution for various applications.

Lastly, we discussed the benefits of air compressors, which can enhance the performance of pneumatic tools, making tasks quicker and more efficient.

Each of these tools contributes to the overall quality of your work, making it essential to invest in high-quality options.

Encouragement to Start or Improve Upholstery Projects: Elevate Your Craft

As you consider diving into or enhancing your upholstery projects, it’s crucial to recognize the value of investing in quality tools.

High-quality tools not only improve the efficiency of your work but also significantly impact the final results.

Whether you’re a seasoned professional or a DIY enthusiast, using the right tools can elevate your craft and enhance the satisfaction you derive from your projects.

By equipping yourself with reliable and durable tools, you’ll find that the process becomes more enjoyable, and the outcomes reflect your dedication to craftsmanship.

Don’t hesitate to explore new tools and techniques; each investment you make in your toolkit is a step towards achieving stunning upholstery results.

Final Tips or Advice: Building a Reliable Toolkit for Upholstery

To build a versatile and reliable toolkit for upholstery, start by prioritizing essential tools that cater to your specific needs.

Focus on acquiring high-quality versions of the basics, such as staple guns, scissors, and adhesive options, as these will serve you well across various projects.

It’s also beneficial to consider the ergonomics and functionality of each tool; comfort during use can significantly enhance your efficiency and reduce fatigue.

Don’t forget to regularly maintain your tools to ensure they remain in top condition, as this will prolong their lifespan and improve performance.

Additionally, always be open to learning new techniques and adapting your toolkit as you gain experience.

With a well-chosen set of tools and a commitment to safety and quality, you’ll be well-equipped to tackle any upholstery project that comes your way.